Since its foundation in 2009, the Thermal Equipment Plant "Alternative Energy" has been developing and manufacturing modern heating equipment based on induction electric heaters operating at a common industrial frequency, which are known on the world market under the brand name "VIN" and "VIN-PROM".

экологически чистые технологии с целью получения дешевой

тепловой энергии по всему миру, используя новейшие

разработки в области теплоэнергетики и физики. В перспективе

получение бесплатной электрической энергии.

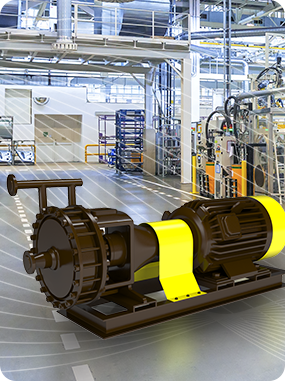

This is a complete high-tech thermal equipment designed for heating oil, petrochemicals and other petroleum-containing fluids.

ADVANTAGES

- The generator does not require a heat exchanger – oil or petroleum-containing fluid is heated by passing through the heat generator. Oil treated in a cavitation generator changes its rheological properties.

- The generator is used for the destruction of persistent salt-water capsules in oil, as a result, the process of separating water from oil at oil treating facilities is efficient and dynamic.

- The generator is used to obtain stable, finely-divided emulsions of oil, fuel oil and diesel fuel, with various fluids.

- The generator heats the fluid by friction of the fluid molecules and cavitation, easily integrated into production lines where heating of fluid is required.

- VTGNH generator does not have to replace the existing techniques of heating and procession of the oil and petroleum-containing fluids. The generator is easily integrated into operating production lines and technical processes, while the process itself becomes more efficient and dynamic. Significantly reduced the cost of heating and preparation of raw materials for further technological processes.

OPERATION PRINCIPLE OF OUR EQUIPMENT WHICH ENSURES ITS EFFICIENCY

The equipment allows to destroy already formed paraffin molecules at the molecular level, to weaken the bonds of a dense crystal lattice, to reduce their ability to stick together simultaneously with heating due to the effect of cavitation.

At the same time, the pour-point depressant molecules supplied to the zone of heating and active cavitation treatment of the fuel come into contact with paraffin molecules and thereby stop the growth of the crystal lattice at the crystallization spot.

Economy component. All included costs increase the price of fuel by a maximum of 2%.

Interaction with on project manager with whom you can resolve all issues from order approval and selection of equipment to installment payment plan.

We can provide a service as follows:

- Analysis of thermal, hydraulic and technological scheme

- Selection of the optimal solution for the power calculation

- Development of a basic or individual product order

- Tailored configuration of additional equipment and components for each Customer

- Delivery of products to the Customer or local pickup

All products are certified and patented in the Russian Federation and EU which gives you a guarantee of obtaining a high-quality and reliable tool for solving the problems of organizing efficient heat supply for industrial building and structures, hot water supply and ventilation, heating oil and petroleum products and industrial processes.

INDUCTION BOILERS FOR HEATING AND HOT WATER SUPPLY OF THE HOUSE

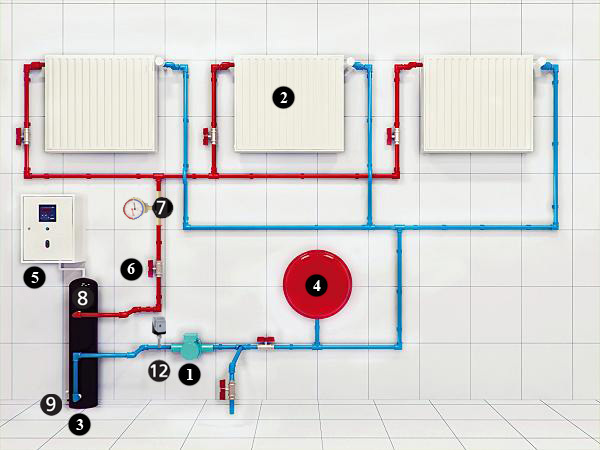

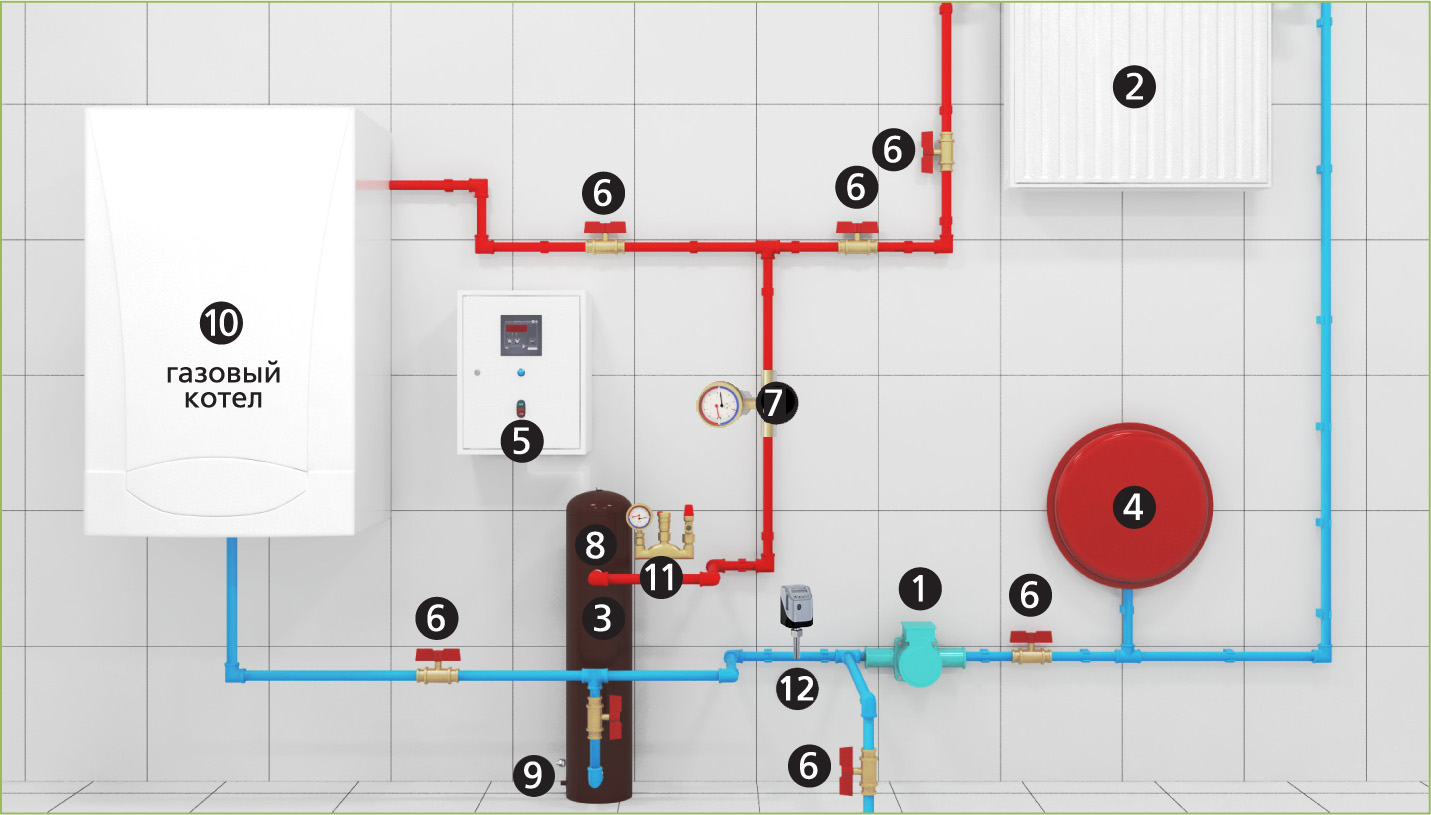

2. Heating radiators

3. Induction boiler

4. Membrane tank

5. Control cabinet

6. Ball valves

7. Temperature sensor

8. Emergency stop sensor

9. Grounding

11. Safety assembly

12. Flow sensor

(This equipment is not included in the induction boiler delivery set)

3. Induction boiler, 4. Membrane tank

5. Control cabinet, 6. Ball valves, 7. Temperature sensor, 8. Emergency stop sensor, 9. Grounding, 11. Safety assemby, 12. Flow sensor. (This equipment is not included in the induction boiler delivery set)

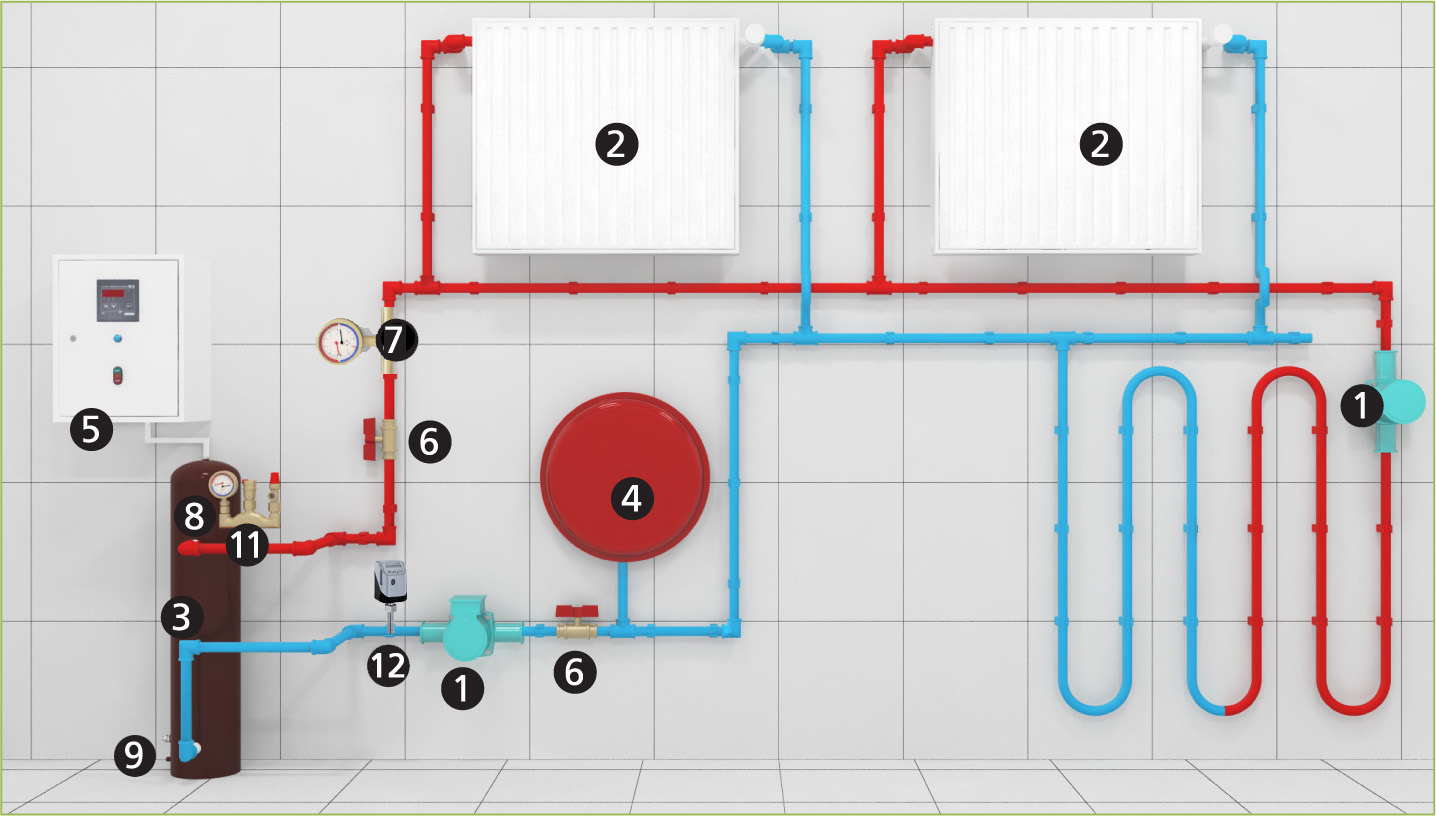

2. Heating radiators

3. Induction boiler

4. Membrane tank

5. Control cabinet

6. Ball valves

7. Temperature sensor

8. Emergency stop sensor

9. Grounding

11. Safety assembly

12. Flow sensor

(This equipment is not included in the induction boiler delivery set)

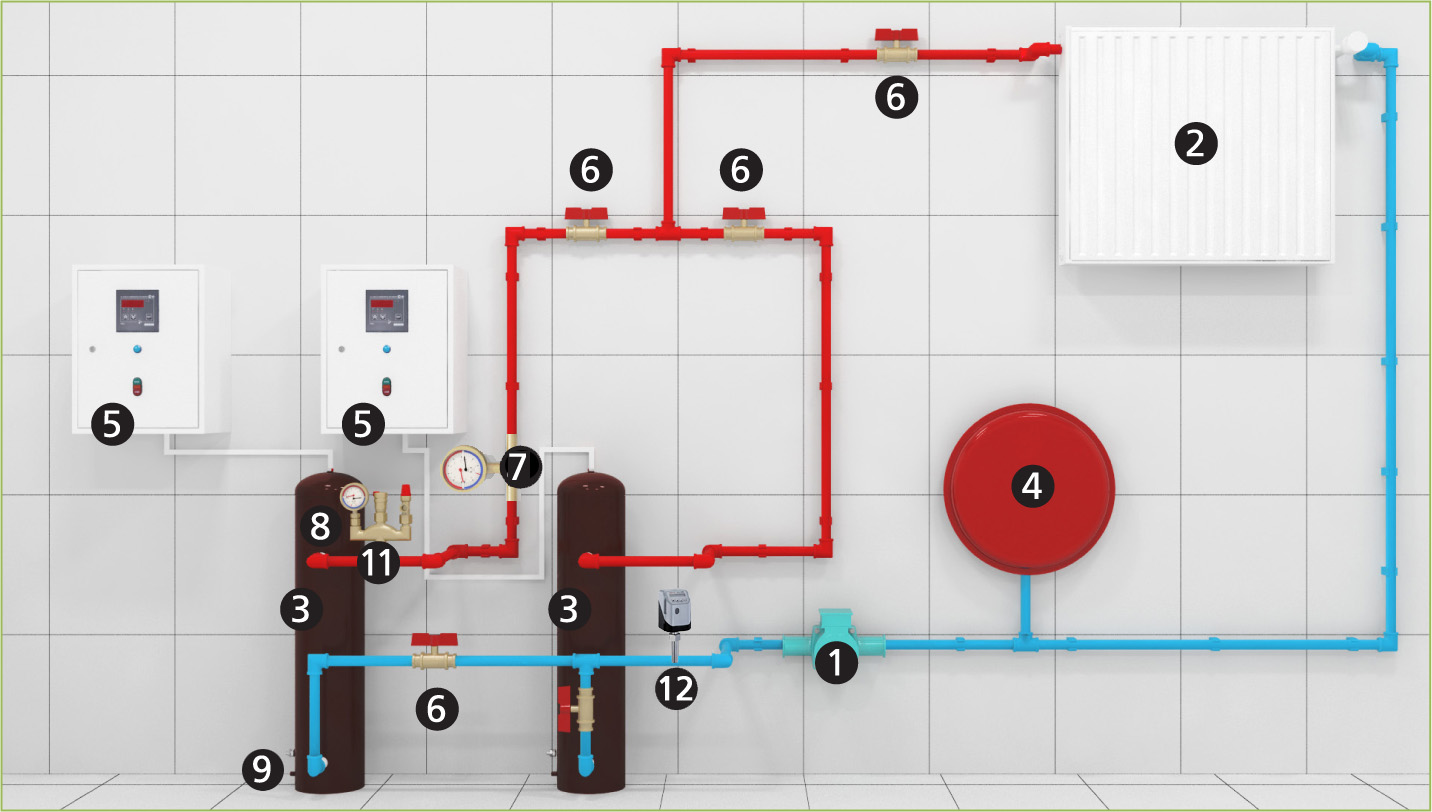

2. Heating radiators

3. Induction boiler

4. Membrane tank

5. Control cabinet

6. Ball valves

7. Temperature sensor

8. Emergency stop sensor

9. Grounding

11. Safety assembly

12. Flow sensor

(This equipment is not included in the induction boiler delivery set)

2. Heating radiators

3. Induction boiler

4. Membrane tank

5. Control cabinet

6. Ball valves

7. Temperature sensor

8. Emergency stop sensor

9. Grounding

11. Safety assembly

12. Flow sensor

(This equipment is not included in the induction boiler delivery set)

INDUCTION BOILERS

FOR INDUSTRIAL FACILITIES

Our modern production allows us to solve any problems. If you did not find suitable equipment, send us your technical requirements and our specialists will offer the most efficient and cost-effective solution.

Application area:

- Autonomous heating of buildings, structures, social facilities, etc. with a lack of centralized network capacity / during the off-season

- Autonomous heat supply for shift camps and temporary structures

- Heating of buildings, structures in the autumn-spring period to maintain the set temperatures

- Decentralization of heat supply

- Heating up the heat carriers of centralized heating networks

- In addition, the equipment does not require special premises for installation, it is possible to install it in existing buildings and premises, including social ones.

All elements are optimally matched for efficient operation. The complete set of equipment allows to significantly simplify installation and reduce the risk of failure during further operation.

Moreover, various options for monitoring and control systems are selected for the heating unit, including remote control and management, which can be selected according to the Customer’s needs.

Application area:

- Autonomous heating of buildings, structures, social facilities, etc. with a lack of centralized network capacity / during the off-season;

- Autonomous heat supply for shift camps and temporary structures;

- Decentralization of heat supply;

- Heating up the heat carriers of centralized heating networks.

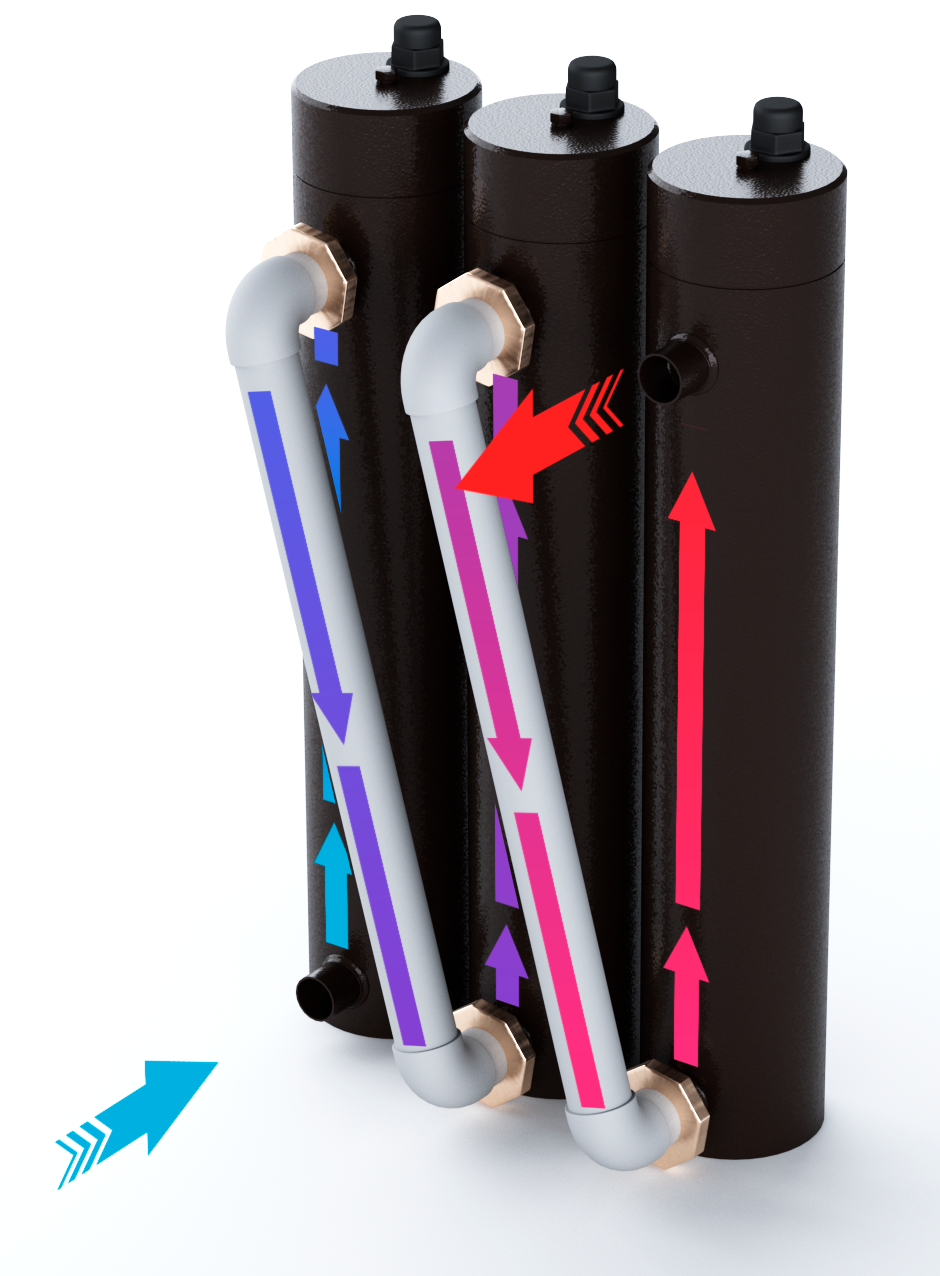

The principle of inductor heater operation is quite simple – the magnetic fields generated by the inductors heat the walls of the heat exchanger, which in turn heat the heat carrier, whether it be water, oil or any other fluid.

Modular heating unit Titan-M, depending on the Customer’s requirements can be equipped with several induction heaters, heat exchangers and other specific technological elements. Titan-M is extremely safe and functional.

Modular heating unit Titan-M has been tested in various climatic and technological conditions. It is a versatile and standalone solution that makes it possible for you to get it up and running in a matter of hours (minutes) and its use does not require special skills or expensive training.

The VIN-PLUTON individual heating station is built on the basis of one or several VIN-PROM vortex induction heaters and has all its advantages.

The principle of inductor heater operation is quite simple – the magnetic fields generated by the inductors heat the walls of the heat exchanger, which in turn heat the heat carrier, whether it be water, oil or any other fluid.

Depending on the customer’s requirements, the VIN-PLUTON individual heating station can be equipped with several induction heaters, heat exchangers and other specific units. VIN-PLUTON is a unique solution for management companies and industries of any size.

It has been adapted to various climatic and technological conditions and has established itself as a unique solution for heating the heat carrier at minimal cost.

Application area and advantages:

- Autonomous hot water supply and heating systems for administrative and industrial building and structures.

- Reducing the set power of the heater by two or more times, comparing to the flow type electric heaters. Smoothing “peak” loads of electricity and water consumption and elimination a number of frequently occurring restrictions, the solution of which entails significant financial costs (for cable cross-section, for limited permitted power, etc.)

- Heating of water in tanks, up to maximum temperature at night, at reduced tariffs for electricity.

- At peak consumption, unit is using the hot water stored in the tank and at minimum water consumption, the unit operates in the mode of maintaining the temperature in the storge tank.

- The VIN-LOGOS unit can be used to heat water for technological purposes.

«VIN-NEPTUN»

Application area:

- The main source of hot water for technological and domestic needs

- Autonomous hot water supply and heating systems for administrative and industrial building and structures

- Heating of food, chemical and petrochemical fluids

- Heating up the water for the needs of hot water supply with insufficient parameters of centralized supply system

- Hot water supply of remote stationary residential facilities

- Reduction of set heater power by two or more times comparing to flow type electric heaters

- Smoothing “peak” moments of power and water consumption. The main heating can be carried out at night and during the day the unit will work in heating up mode.

«VIN-URAN»

VIN-URAN is built on the basis of the VIN-PROM vortex induction heater and has all its advantages – high fire and electrical safety, unpretentiousness, stability and efficiency.

The work principle of an induction heater is fundamentally different from heating with tubular heating element – the magnetic fields generated by the inductors heat the walls of the heat exchanger, which in turn heat the heat carrier, whether it be water, oil or any other fluid.

The heat carrier already heated to the required temperature heats the coil heat exchanger located in the electroplating bath, thereby heating the chemical solution.

Thus, the transition to the use of the VIN-URAN vortex induction heater significantly increases the reliability, safety and profitability of electroplating production.

The VIN-URAN heating system has been tested under various conditions and is a standalone and reliable solution. It is possible to integrate this system into any production process without costly downtime.

The work principle is quite simple - – the magnetic fields generated by the inductors heat the walls of the heat exchanger, which in turn heat the heat carrier, whether it be water, oil or any other fluid, such as mixture of water with ethylene glycol.

The VIN-VULKAN system operates in a completely autonomous mode, heating the heat carrier to a temperature in a range from 90°С to 115°С and driving it through a spiral or coil-type heat exchanger installed in the tank. VIN-VULKAN tank heating units provide power from 10 kW to 6 MW and operate at industrial frequency currents of 50Hz, without requiring special converters.

VIN-VULKAN has been tested in various conditions and is a reliable, safe, efficient and durable solution that makes it possible for you to confidently integrate it into any process without excessive start-up and operating costs.

- Heating of oil in front of metering units

- Heating of high-viscosity oil

- Oil heating

Features of "VIN-SPN":

"VIN-SPN" is manufactured on the basis of induction electric heaters at industrial frequency currents on the meringue of the HEATING NODE "VIN-TITAN"

.

Among all electric heaters, induction heaters are the most reliable, durable and safe. The design of the induction heater is patented and fundamentally different from other types of electric heaters.

Many years of operational experience have proven the reliability of induction heaters in the most difficult and unfavorable working conditions at the enterprises of the Russian oil complex, such as Rosneft, Belkamneft, Lukoil and others.

Types of tasks to be solved for the oil and gas complex:

- Local heating of oil on the section of the technological pipeline transported, respectively, to the points of accounting and delivery of oil, as well as local heating of oil on the sections of the main technological pipelines, for its transportation over long distances

- Local heating of oil and natural gas supplied to gas turbine installations, boilers, etc.

- Maintaining the temperature of oil or gas in dead-end sections of technological pipelines

- Temperature maintenance in oil storage tanks (tank farms of oil storage facilities)

- Maintaining the water temperature of fire-fighting tanks

- Heating of oil in bullite tanks for the technological process of oil dewatering, as well as in other cases where preliminary preparation of oil (separation, desalination, etc.) is required in oil fields before its transportation

- Heating of fuel oil or oil supplied for combustion in boilers

- Autonomous and centralized heat supply for heating, hot water supply and ventilation of facilities

We are ready for new developments of electric heating equipment for the oil industry on individual orders.

With hydrodynamic heating of the liquid, heat losses are completely eliminated, as when using equipment with a heat exchanger. The simplicity of the design of the VTG heat generator ensures reliability both in operation and in maintenance. The costs of its operation are similar to the costs of operating a centrifugal pump of equal power. All this increases the efficiency of processes, ensures unpretentiousness, autonomy and economy.

The VTG heat generator is able to quickly heat any liquid to a set temperature — water, oil, diesel fuel and other petrochemical liquids. The heated liquid is fed through the central channel into the working area of the heat generator, separated by a rotating rotor. Under the action of centrifugal forces, the liquid moves, filling special holes on the surfaces of the rotor and both covers.

Due to the creation of areas of reduced pressure in these holes, the process of cavitation — collapse of bubbles occurs, leading to the formation of micro-explosions accompanied by active heat release, and as a result, to an almost instantaneous increase in the temperature of the heated liquid.

Due to the minimal amount of heating losses and the simplicity of the design, our customers actively use VTG heat generators in the petrochemical industry and in mechanical engineering. It is used even by rescue services, while using mobile versions powered by a diesel engine.